Oberdorfer™ centrifugal pumps have a single rotating metal impeller. Liquid enters at the center and is thrown outward radially by centrifugal force. The impeller is not in contact with other pump parts resulting in quiet, efficient, pumping action. The flow produced is not positive which permits the discharge line to be shut off completely without danger of overloading motors or bursting lines. Consequently a relief valve is not required. The liquid flow varies directly as the pump speed—the higher the speed the greater the flow. Horsepower required varies directly as flow and pressure. Maximum horsepower is required with a wide open discharge line. This is the point of maximum flow. With a throttled discharge, the flow decreases at a greater rate than the pressure increases thereby requiring less horsepower at the higher pressures. This is known as an “unloading” feature of the pump.

Available Options

- 109MB pump only (OB109MB)

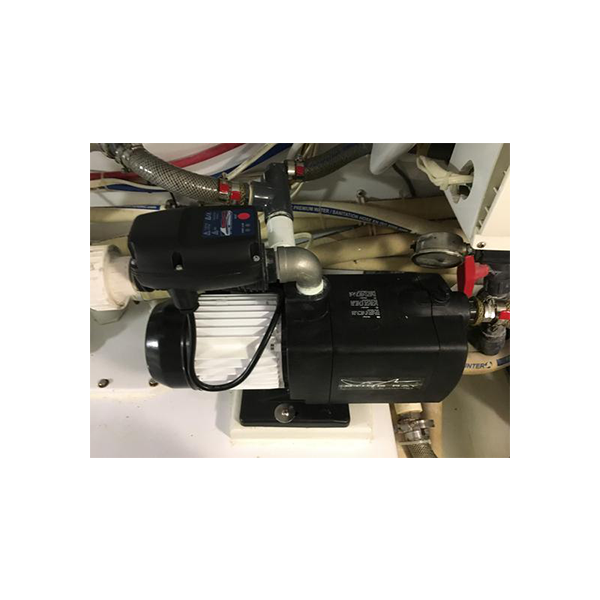

- 109MB-J19 pump and ½ hp open motor (109MB-J19)

- Motor 10J36BJ-Cent (10J36BJ-Cent)

FEATURES

- Rugged Bronze Construction

- A Standard in the Marine Air Conditioning Industry

- Extremely Quiet Operation

- O-Ring Housing seal eliminates gasket problems

- Polytetrafluoroethylene (PTFE) Barrier Seal to protect motor bearings

- Handles Contaminated Liquids

- Discharge port orientation flexibility-8 positions

- Mechanical Seal - Carbon/Ceramic, Nitrile - standard, Fluoroelastomer (S10) optional, Polytetrafluoroethylene (PTFE)(S11) optional

- Pump Heads mount to standard footed Nema 56J Jet Pump Motors

- Shafts: 416 Stainless, Nickel Alloy, or 316 Passivated Stainless

- Multiple motor options available

- For Industrial Version - see Model 700 series

DRIVE

This close-coupled pump uses a standard NEMA C-Flange Jet Pump Motor with weld-on base and threaded shaft end to accept the pump impeller. Single phase motors are nonreversible and are wired for the proper pump rotation which is counter-clockwise looking at the inlet end of the pump. (See the dimensional drawing.) Three phase motors must be checked out for proper rotation when the pump is installed. Interchanging of any 2 wires in a 3-phase system will reverse motor rotation.

LIQUIDS & TEMPERATURES

The special pump alloys used provide corrosion resistance to many liquids including water, water solutions, and a wide range of commercial chemicals. Questions as to the chemical compatibility of special liquids should be referred to the factory.

The pump uses a mechanical type shaft seal with a Nitrile rubber element. It is suitable for water, oils, and some mild solvents and it is limited to 212°F and 75 P.S.I. Fluoroelastomer (S10) seals and Polytetrafluoroethylene (PTFE) (S11) seals are available for severe solvents and difficult chemicals.

Viscous liquids with a maximum viscosity of 2000 Saybolt Seconds Universal can be pumped. However, when pumping viscous liquids as compared with water, a reduction in flow and pressure occurs and the required horsepower rate increases.

Liquids heavier than water require additional horsepower in direct proportion to the increase in specific gravity. Liquids contaminated with small solids or abrasives can be handled, but a reduction in mechanical seal life must be expected.

SUCTION LIFT

These centrifugal pumps are not self-priming. They must be installed below the liquid level so that the liquid flows to the pump by gravity (flooded suction). However, if a foot valve is used at the beginning of the suction line and all air is bled from the pump by manual priming, the pump will lift on the suction side up to 15 feet. Such a system relies entirely on a non-leaking foot valve for starting capability.

Shipping & Returns

Standard ground shipping is free for orders over $250. This excludes some products such as hazardous or oversized items. Learn More

30 Day return policy: Products returned in original packaging will be refunded if returned within 30 days of purchase. Products purchased after 30 days may be returnable subject to a restocking fee.